TECHNOLOGY

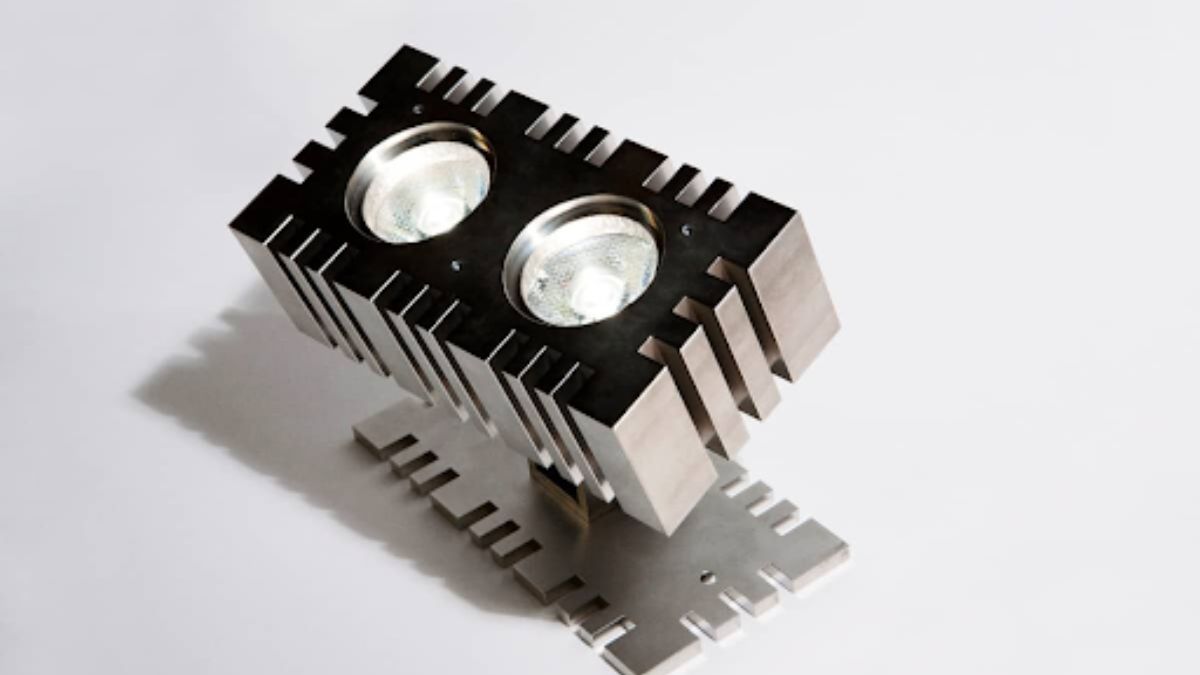

The Secret to Success Wire EDM Aluminum

Wire EDM, or Electrical Discharge Machining, has become a popular method for cutting intricate shapes and complex parts with high precision in the metal fabrication industry. This process uses electrical discharges, or sparks, to remove material, making it ideal for hard metals like steel, titanium, and tungsten. However, cutting softer metals like aluminum becomes a bit more nuanced.

Aluminum is a widely used metal in industries such as aerospace, automotive, and electronics due to its lightweight and corrosion-resistant properties. However, working with aluminum using wire EDM requires a specific approach to avoid potential challenges such as wire breakage or overheating. This article delves into the ins and outs of wire EDM aluminum, providing useful tips and guidelines to ensure you get the best results from this innovative machining process.

What is Wire EDM Aluminum?

Wire EDM (Electrical Discharge Machining) is a specialized technique that removes material from electrically conductive materials using a thin wire as an electrode. The process relies on the spark erosion mechanism, where electrical discharges create tiny sparks that erode the material bit by bit. The wire is usually made from brass or copper and never touches the workpiece, as the erosion happens due to the spark between the wire and the material.

The process remains the same when applying wire EDM to aluminum, but certain precautions must be taken. Aluminum is softer than many other metals typically used in wire EDM, which can be prone to warping, deformation, or excessive wear on the wire if not handled properly. However, with the correct setup, wire EDM aluminum can result in highly accurate and intricate cuts, making it a preferred choice for many manufacturers of this versatile metal.

The advantages of using wire EDM for aluminum are clear. The non-contact nature of the process means there’s no risk of mechanical damage or deformation, and its precision ensures that even the most complex shapes can be accurately produced. Wire EDM also allows for tight tolerances and smooth surface finishes, making it ideal for industries where precision and accuracy are paramount.

How Does Wire EDM Aluminum Work?

The process of wire EDM aluminum begins by setting up the machine to run the electrical discharges through a thin wire electrode. The workpiece, in this case, an aluminum block or sheet, is submerged in deionized water to act as a dielectric fluid. This fluid cools the material and washes away the eroded particles, ensuring a clean and efficient cutting process.

One key factor in working with aluminum using wire EDM is controlling the heat. Aluminum has high thermal conductivity, which can heat up quickly during cutting. Excessive heat can lead to wire breakage or cause the material to deform. Therefore, the cutting speed, wire tension, and discharge energy must all be carefully managed to ensure a smooth and successful cut.

The wire moves along a predefined path according to the CAD design, and the machine uses precise coordinates to generate the spark discharges needed to cut through the aluminum. The wire never comes into contact with the material directly, which reduces the risk of burrs or rough edges, resulting in a smooth finish. Additionally, wire EDM can cut extremely thin or intricate features in aluminum that would be challenging to achieve with traditional machining methods.

Tips for Wire EDM on Aluminum

Adopting a few best practices is essential when using wire EDM for aluminum to ensure optimal performance and results. Below are some tips to make the most of your wire EDM metal service when working with aluminum:

-

Control the Heat

As mentioned earlier, heat management is crucial when machining aluminum using wire EDM. Aluminum’s high thermal conductivity can cause it to absorb heat faster than other metals, leading to potential problems such as wire breakage or material warping. To avoid this, the discharge energy is reduced, and the cutting speed is lowered to minimize the heat generated during the process. Deionized water as a cooling medium is essential in effectively dissipating heat.

Another way to manage heat is to increase the dielectric fluid’s flushing pressure. This ensures that the eroded particles are quickly removed from the cutting zone, reducing the chances of overheating. Proper flushing also helps maintain the wire’s integrity and prevent premature breakage, which is common when cutting softer metals like aluminum.

2. Choose the Right Wire

The type of wire used in wire EDM significantly affects the cut quality and the machining process’s overall success. Coated wires, such as zinc-coated brass wires, are advisable for cutting aluminum. These wires offer better wear resistance and increased cutting speed, making them more efficient for aluminum.

Brass wires are generally preferred due to their conductivity and durability. Additionally, using thinner wires allows for more precise and intricate cuts, particularly useful when working on complex shapes and designs.

3. Optimize Machine Settings

Aluminum requires specific settings in the EDM machine to avoid issues like excessive wear or breakage. Reducing the discharge current, decreasing pulse duration, and adjusting the wire tension can help maintain stability during cutting. A slower feed rate can also ensure smoother cuts and prevent unwanted deformation.

Machine parameters must be monitored and adjusted regularly throughout the process to achieve the best results. Test cuts on scrap aluminum are recommended to fine-tune the machine before starting on the final workpiece.

4. Prevent Oxidation

Aluminum is prone to oxidation when exposed to air, which can interfere with the wire EDM process. To prevent this, consider applying a protective coating to the material or using a controlled environment with minimal exposure to oxygen during cutting.

Additionally, maintaining a clean work area and ensuring that the aluminum is free from contaminants before starting the wire EDM process can help improve the quality of the cut. Oxidation or contamination on the material’s surface can lead to rough edges or incomplete cuts, which may require additional finishing.

5. Use Taper Cuts for Complex Shapes

One of wire EDM’s main advantages is its ability to create taper cuts, which are angled cuts that can follow complex geometries. When working with aluminum, taper cuts are especially useful for producing parts with varying thicknesses or intricate features that would be difficult to achieve with other machining methods.

Adjusting the wire’s angle during the cutting process allows you to create precise taper cuts without compromising accuracy or surface finish. This is particularly beneficial in industries requiring complex designs and tight tolerances.

6. Ensure Proper Flushing

Flushing is a crucial aspect of wire EDM, particularly when working with materials like aluminum. The dielectric fluid (usually deionized water) is essential for cooling and removing the tiny particles eroded from the workpiece during cutting. Ensuring proper flushing pressure keeps the cutting zone free of debris, reducing the risk of overheating or wire breakage. If the flushing pressure is too low, particles can accumulate in the cutting area, which can cause poor finishes or even wire snapping.

Additionally, constant flushing helps maintain a consistent temperature in the cutting area, ensuring even cuts and preventing distortion in softer metals like aluminum. Ensure your machine’s flushing system is optimized before starting the process.

7. Monitor Wire Wear

Wire wear is a common challenge in wire EDM, and it can happen faster with aluminum than with harder materials. Monitoring wire wear is essential to ensure consistent cutting performance. If the wire becomes too worn, it may not generate the required electrical discharge effectively, resulting in rough edges or incomplete cuts.

To avoid this, regularly inspect the wire during the process and replace it if necessary. Automated wire threading systems can help maintain efficiency by quickly replacing worn-out wire sections. Using a high-quality, coated wire can also reduce wear and extend the wire’s lifespan, ensuring a more consistent cutting performance throughout the process.

Conclusion

Wire EDM is an incredibly effective technique for machining aluminum. It provides a high level of precision and accuracy without the need for physical contact with the material. When applied correctly, it allows for intricate cuts, smooth finishes, and consistent results, making it ideal for industries that require complex aluminum parts.

However, achieving success with wire EDM aluminum requires a good understanding of the material’s properties and the process. Proper heat management, wire selection, and optimized machine settings are essential to avoid common pitfalls such as wire breakage or material deformation. By following these best practices, you can ensure your wire EDM projects are successful and efficient.

Incorporating wire EDM into your wire EDM metal service can help you fully take advantage of this process’s benefits, particularly when working with softer metals like aluminum. Whether you’re producing parts for aerospace, automotive, or electronics applications, wire EDM offers precision and versatility that traditional machining methods simply cannot match.

TECHNOLOGY

Exploring the Aesthetic: Isabelle Lynn Kertzie’s Instagram Journey

Isabelle Lynn Kertzie has taken Instagram by storm, drawing in an audience captivated by her unique aesthetic. With a keen eye for detail and an innate sense of style, she transforms everyday moments into visual poetry. As you scroll through her feed, it’s clear that each post is more than just a snapshot; it’s a carefully curated piece of art that resonates with thousands. But how did this ordinary social media experience evolve into the stunning journey we see today? Let’s delve deeper into Isabelle’s Instagram adventure and uncover what makes it so special.

From ordinary posts to curated aesthetic: Kertzie’s evolution on Instagram

Isabelle Lynn Kertzie’s Instagram journey tells a captivating story of transformation. Initially, her posts reflected everyday moments—snapshots of life that resonated with many.

As she explored her creative side, those ordinary images began to shift. Each post became more intentional, weaving together themes and colors that spoke to her unique style. Kertzie embraced visual storytelling, moving away from random uploads.

Her feed blossomed into a curated aesthetic that caught the eye of followers everywhere. Every photo seemed purposeful and thought-provoking—a reflection of not just what she saw but how she felt.

This evolution didn’t happen overnight; it was a gradual process filled with experimentation and self-discovery. With each new post, Isabelle showcased not only artistry but also an evolving identity within the vast landscape of social media culture.

The impact of Kertzie’s aesthetic on her followers and the social media community

Isabelle Lynn Kertzie’s Instagram aesthetic has become a vibrant source of inspiration for many. Her carefully curated visuals resonate deeply with followers, creating a sense of connection and community.

Each post invites her audience into a world filled with color, texture, and emotion. This artistic approach encourages others to explore their own creativity. Followers often find motivation in the way she presents everyday moments through an imaginative lens.

Kertzie’s aesthetic also fosters engagement within the social media landscape. People flock to her posts not just for visual pleasure but also for shared experiences and ideas. The comments section buzzes with conversation, as fans exchange thoughts on their favorite elements or styles inspired by her work.

In this era of constant scrolling, Isabelle’s feed stands out as a reminder that beauty can be found in both simplicity and complexity alike.

Behind the scenes: How Kertzie creates and maintains her aesthetic

Isabelle Lynn Kertzie’s aesthetic is not just a happy accident; it’s the result of careful planning and creativity. She dedicates time to curating her feed, selecting colors and themes that resonate with her personal style.

Kertzie often finds inspiration in everyday life—nature, fashion trends, or even art. Each photo captures a moment that speaks to her vision. She pays attention to lighting and composition, ensuring each post looks polished yet authentic.

Editing plays a significant role too. Kertzie utilizes various apps to enhance her images while keeping them true to her brand identity. Consistency is key; she sticks to specific filters that unify her visuals.

Her followers appreciate the effort behind every post, which fosters deeper connections. This engagement inspires Kertzie further as she continues refining her unique aesthetic journey on Instagram.

The challenges of maintaining an aesthetic and staying true to oneself

Maintaining a distinct aesthetic on Instagram can be both rewarding and challenging. For many, the pressure to keep up with trends can overshadow personal creativity.

Isabelle Lynn Kertzie navigates this delicate balance daily. While she curates stunning visuals, there’s always that nagging worry about authenticity. Followers expect consistency, yet each post is a reflection of her evolving self.

The struggle often lies in wanting to please an audience while staying true to individual expression. Authentic moments might clash with the polished vibe that garnered attention in the first place.

Moreover, inspiration can ebb and flow unexpectedly. What once felt vibrant may begin to feel stale or forced over time.

It’s easy to lose sight of why one started sharing content originally amidst external expectations and pressures from the social media landscape. The heart of it all remains: balancing artistic vision with genuine self-expression takes constant effort and introspection.

Lessons learned from Kertzie’s Instagram journey

Isabelle Lynn Kertzie’s Instagram journey offers valuable insights into the world of social media. One key lesson is the importance of authenticity. Followers connect more deeply when they sense genuine passion behind content.

Additionally, consistency plays a crucial role in building an engaged community. Regularly posting cohesive visuals and themes keeps followers coming back for more. This effort fosters loyalty over time.

Embracing creativity is another takeaway from her experience. Kertzie showcases that experimentation can lead to unexpected successes, encouraging others to break free from conventional norms.

Balancing personal expression with audience expectations is vital. While it’s tempting to cater solely to trends or likes, staying true to oneself ultimately resonates most powerfully with followers.

Conclusion: The power of aesthetics in

The journey of Isabelle Lynn Kertzie on Instagram is a testament to the transformative power of aesthetics. Her evolution from ordinary posts to a carefully curated aesthetic has captured the attention of many. It’s more than just visuals; it’s about storytelling and connection.

Kertzie’s impact resonates deeply within her community, inspiring followers to embrace their own creative journeys while fostering a sense of belonging. Behind her stunning feed lies dedication, planning, and an unwavering commitment to authenticity.

Maintaining such an aesthetic brings its unique challenges. Yet, Kertzie navigates these hurdles with grace, reminding us that staying true to oneself is paramount in the ever-changing landscape of social media.

Her story offers valuable lessons for anyone looking to enhance their online presence. Aesthetic isn’t merely surface-level; it’s about expressing identity and connecting with others who share similar passions.

Isabelle Lynn Kertzie’s Instagram serves as a powerful reminder: aesthetics have the ability not only to beautify our feeds but also to enrich our lives through shared experiences and creativity.

TECHNOLOGY

What Is Atlas Physical Therapy and Why Is It Trending?

Atlas Physical Therapy has steadily become a standout in the healthcare sector due to its commitment to personalized, evidence-based care. Rooted in holistic healing and functional movement science, Atlas offers a distinct and refreshing approach to recovery and rehabilitation. Whether you’re recovering from surgery, managing chronic pain, or aiming for peak athletic performance, Atlas has gained popularity for doing more than just “fixing injuries”—they’re transforming lives.

The growing attention to physical therapy as a preventative and restorative care option places Atlas at the center of a societal shift toward non-invasive, empowering, and sustainable health practices. From athletes to seniors and children, the results speak volumes—and so do the patients.

The Vision and Philosophy Behind Atlas Physical Therapy

The founding philosophy of Atlas Physical Therapy is simple but powerful: “Movement is medicine.” Built on the understanding that every individual’s journey is unique, Atlas emphasizes human connection, scientific precision, and emotional support.

Rather than taking a one-size-fits-all approach, the therapists at Atlas tailor each session, adjusting techniques based on progress, pain levels, and personal goals. Their core values—empathy, innovation, transparency, and trust—are deeply woven into their practice, ensuring that patients don’t just feel treated, but truly cared for.

Comprehensive Services Offered at Atlas Physical Therapy

Atlas Physical Therapy offers a wide array of services that address different needs, including:

-

Orthopedic physical therapy

-

Neurological rehabilitation

-

Sports injury recovery

-

Pediatric physical therapy

-

Geriatric mobility therapy

-

Post-surgical rehabilitation

-

Dry needling and cupping

-

Manual therapy

-

Functional movement screening

-

Telehealth and home exercise programs

These services are designed to cater to short-term goals (like healing an injury) and long-term wellness strategies (like posture correction and chronic pain management).

Evidence-Based Therapies Practiced at Atlas

Evidence drives every decision at Atlas. The team incorporates the latest peer-reviewed research into therapy plans. Modalities include:

-

Therapeutic ultrasound

-

Neuromuscular electrical stimulation (NMES)

-

Joint mobilization and manipulation

-

Functional dry needling

-

Kinesiology taping

-

Corrective exercise programming

Therapists stay updated through continuous professional development, ensuring best-in-class treatment at every visit.

Atlas Physical Therapy’s Unique Areas of Specialization

Atlas doesn’t just offer general physical therapy—they go deep into specialties that require advanced skill sets, such as:

-

Vestibular therapy for balance and dizziness disorders

-

Temporomandibular joint (TMJ) dysfunction treatment

-

Concussion recovery programs

-

Women’s health physical therapy (e.g., pelvic floor therapy)

-

Post-stroke mobility training

These specialized programs differentiate Atlas from clinics that merely address surface-level symptoms.

What Conditions Does Atlas Physical Therapy Treat?

Atlas Physical Therapy treats a wide range of conditions, such as:

-

Lower back pain and sciatica

-

Neck and shoulder discomfort

-

Knee injuries and arthritis

-

Post-surgical complications

-

Carpal tunnel syndrome

-

Tendinitis and bursitis

-

Scoliosis

-

Plantar fasciitis

-

Balance and coordination issues

By targeting root causes—not just symptoms—Atlas helps patients regain control and confidence in their bodies.

Conclusion: Is Atlas Physical Therapy the Right Choice for You?

If you’re looking for a partner in health who sees you as more than just a diagnosis, Atlas Physical Therapy may be your best decision. Their modern approach blends science, compassion, and customization to deliver real results. Whether you’re an athlete aiming for excellence, a parent seeking care for your child, or someone recovering from surgery—Atlas meets you exactly where you are.

Your body deserves a trusted guide. At Atlas Physical Therapy, you’re not just healing—you’re evolving.

TECHNOLOGY

Telemetryczny: Understanding Telemetry and Its Applications

Introduction

The term “telemetryczny” (Polish for “telemetric”) refers to systems and technologies that enable the remote measurement and transmission of data. Telemetry plays a crucial role in various industries, including healthcare, automotive, aerospace, and environmental monitoring. This article explores the concept of telemetry, its applications, benefits, and future trends.

What Is Telemetry?

Telemetry is the automated process of collecting data from remote or inaccessible sources and transmitting it to receiving equipment for monitoring and analysis. The word “telemetryczny” derives from Greek roots:

-

“Tele” (remote)

-

“Metron” (measure)

Modern telemetry systems use sensors, wireless communication, and data processing tools to provide real-time insights.

How Telemetry Works

A typical telemetry system consists of:

-

Sensors – Detect physical parameters (temperature, pressure, speed, etc.).

-

Transmitters – Send collected data via wired or wireless networks (Wi-Fi, Bluetooth, satellite).

-

Receivers – Capture and process incoming data.

-

Data Analysis Tools – Interpret and visualize data for decision-making.

Types of Telemetry Systems

| Type | Description | Applications |

|---|---|---|

| Wireless Telemetry | Uses radio, satellite, or cellular networks | IoT, wildlife tracking |

| Wired Telemetry | Relies on physical connections (Ethernet, fiber optics) | Industrial automation |

| Acoustic Telemetry | Uses sound waves underwater | Marine biology |

| Optical Telemetry | Transmits data via light signals | Medical devices, aerospace |

Applications of Telemetry (Telemetryczny)

1. Healthcare & Medical Telemetry

-

Remote Patient Monitoring (RPM) – Tracks vital signs (ECG, blood pressure) in real time.

-

Implantable Devices – Pacemakers and insulin pumps use telemetry for adjustments.

2. Automotive & Telematics

-

Vehicle Tracking – GPS telemetry helps in fleet management.

-

Connected Cars – Monitors engine performance and driver behavior.

3. Aerospace & Defense

-

Satellite Telemetry – Collects data from space missions.

-

Drone Monitoring – Ensures flight stability and navigation.

4. Environmental Monitoring

-

Weather Stations – Measures temperature, humidity, and wind speed.

-

Wildlife Tracking – Uses GPS collars to study animal migration.

5. Industrial & Manufacturing

-

Predictive Maintenance – Detects equipment failures before they occur.

-

Smart Grids – Monitors electricity distribution efficiently.

Benefits of Telemetry Systems

✅ Real-Time Data Access – Enables instant decision-making.

✅ Cost Efficiency – Reduces manual monitoring efforts.

✅ Enhanced Safety – Critical in healthcare and aerospace.

✅ Scalability – Adaptable for small IoT devices to large industrial systems.

Challenges in Telemetry

⚠ Data Security – Risk of cyberattacks on transmitted data.

⚠ Signal Interference – Wireless telemetry may face connectivity issues.

⚠ Power Consumption – Battery life is a concern for remote sensors.

Future Trends in Telemetry

🔮 5G Integration – Faster and more reliable data transmission.

🔮 AI & Machine Learning – Predictive analytics for smarter telemetry.

🔮 Edge Computing – Reduces latency by processing data closer to the source.

Conclusion

The term “telemetryczny” encompasses a wide range of technologies that revolutionize data collection and analysis. From healthcare to space exploration, telemetry enhances efficiency, safety, and innovation. As technology advances, telemetry systems will become even more integral to our connected world.

-

BUSINESS2 months ago

BUSINESS2 months agoPrince Narula Digital PayPal Success: Transforming Online Payments

-

ENTERTAINMENT2 months ago

ENTERTAINMENT2 months agoHighlights and Analysis: WWE SmackDown Episode 1491 Recap

-

ENTERTAINMENT1 year ago

ENTERTAINMENT1 year agoWWE SmackDown Episode 1488 Delivers a Knockout Performance

-

videos11 months ago

videos11 months agobad hair day episode 1 a sore subject

-

LAW11 months ago

LAW11 months agoAn Intriguing Journey into the Life of Jeff Tietjens

-

HOME1 year ago

HOME1 year agoMaximizing Basement Space: Design Tips from Top Basement Renovation Contractors

-

CELEBRITY2 years ago

CELEBRITY2 years agoDiscovering Edgardo Canales The Life and Journey of Adria Arjona’s Husband

-

News2 years ago

News2 years agoNews JotechGeeks Takes the Spotlight in Tech News World